A Billion Electric Vehicles Are Coming. So What Could Go Wrong?

India’s electric vehicle journey began in 1902 when an electric vehicle was used to ferry passengers between Esplanade and Kidderpore in Kolkata.

With concerns over the environment growing and the government pushing for green mobility across all sectors, India is stepping up its efforts to help individuals switch to electric vehicles.

There is no doubt that India is moving toward rapid progress in electric vehicles. As a result, the country has seen a flood of electric two-wheelers and four-wheelers.

Currently, there are more than five performance-oriented electric two-wheelers available in the country. Several have already launched and are getting price announcements, while a few are still in the works.

Thanks to startups and venture capitalists in India, the electric vehicle (EV) industry is poised to take off. As a result, India will likely be a world leader in EV adoption in the coming years. But only if it fixes these problems.

Clean energy production

EVs aren’t green; most pollution comes from the supply chain and manufacturing. India’s electricity generation is primarily coal-based and produces enormous amounts of pollution. EVs might be an efficient alternative to gasoline-powered cars. However, they still rely on power plants for energy, which pollute the environment at an alarming rate.

Electric vehicles can’t be green until they’re powered by 100% clean, renewable sources, like wind and solar. As of January 2022, India’s reliance on coal for power generation is 51.6%. So in this scenario, owning an EV to go green is an illusion. On the other hand, this could mean that vehicles burn coal instead of gasoline.

Battery swapping and charging experience

A typical EV charges to 100% in about two hours: people who plan ahead might not have a problem in this regard. But if someone has to go out spontaneously, they probably won’t want to wait two hours to charge their car.

Charging also takes up valuable parking space. It may also lead to arguments with other drivers, which could be annoying. There should be enough charging stations throughout the country to avoid long wait times for charging. Else, people will go back to conventional fuel vehicles.

Here, fast-charging stations can reduce the charge time to 20-30 minutes or a battery swap unit that takes the same time filling up a vehicle with petrol or diesel.

Localization

Localization is a key area where we lag behind other countries like China. EVs must be localized to become affordable.

Today, lithium-ion batteries are the technology of choice for electric vehicles. China currently dominates the lithium-ion battery market. More than half of the world’s lithium battery production produced in China, and that number will only rise as EV sales grow.

On a side note, the startup community seems less enthusiastic about battery manufacturing than about making EVs for mass markets.

EV Safety and Standardization Framework

India doesn’t have a clear framework for manufacturing an electric vehicle, including guidelines and certification.

However, the Government of India has a certification process in place for both ICE vehicles and those with hybrid powertrains. The standards and policies for EVs are necessary because we require battery management systems that don’t blow up at the slightest provocation, so certification is critical.

Standardization of Charging Infrastructure

The biggest challenge in making India a manufacturing hub for EVs is standardizing batteries. It requires a strategic approach from the government regarding infrastructure, R&D facilities, and standardization of components.

A lack of EV charging standards will stifle innovation. In time, the ones with the deep pockets will jump in the wagon and then intimidate the EV makers and consumers into imposing their own standards. In addition, if standards are established, consumers won’t have to carry their chargers, and startups can focus on product innovation rather than worrying about charging infrastructure. We must remember – The whole is greater than the sum of its parts

In consultation with the industry, the government of India must release a white paper that offers a standard framework for battery design, size, and specs. Otherwise, chaos will ensue.

Frequent Powercuts

India has a massive power crisis, and frequent power cuts are common occurrences across all cities in the country. If we were to own an electric car, the last thing we want to face is a power cut while charging the vehicle. This is one of the critical reasons carmakers are looking at bringing plug-in hybrids instead of pure EVs. Plug-in hybrids can run both on petrol and battery.

Range Anxiety

Range anxiety is the fear of driving an electric vehicle and running out of power without being able to find a charging station on time to replenish the battery. A recent study found that 50 percent of potential drivers of electric vehicles are uncertain about charging their vehicles when they need to. This can happen, especially when traveling long distances or in remote areas where a charging station may not be easily accessible.

This problem can be solved if the government takes ownership of this issue and uses its institutions, like BHEL or BEL, to create a nationwide infrastructure for EV charging. This can serve many purposes: it can speed up and improve the adoption of electric vehicles. Secondly, it would give the government subsidiaries a boost. Furthermore, people will realize that the government is not just talking but is also walking the talk.

Ethics and the Environment

Lithium-ion batteries will continue to be in demand. This will increase the demand for cobalt, which is a vital component of lithium-ion batteries.

Cobalt has been a popular choice because the metal increases battery life, which in the case of EVs means range, by maintaining a stable battery structure while continuously charging and discharging.

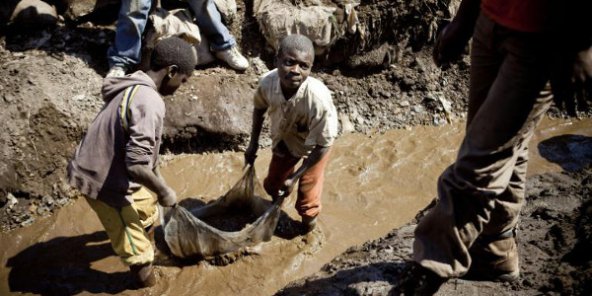

Cobalt is found in countries like Australia and Cuba. Still, more than half of the world’s supply comes from mines in the Congo operated by child labor and militias under unethical conditions. Child labor, abusive working conditions, and health hazards plague the cobalt mining industry.

According to a 2016 Amnesty International report, an estimated 40,000 children work in mines to supply cobalt to the automotive and tech industries. According to the study, children as young as seven years old work in hazardous conditions in artisanal (informal) mines. As a result, there is an increased risk of fatal accidents and severe health problems, such as respiratory diseases and musculoskeletal disorders.

Additionally, lithium extraction from salt lakes produces millions of liters of radioactive wastewater containing arsenic, radium, and other waterborne pathogens. Such wastewater is disposed into rivers and causes further contamination.

Recycling is another challenge. There are not many facilities in India that can recycle EV batteries at scale today.

In conclusion, EVs may not be a solution if we don’t resolve these issues. Instead, they may become the problem masquerading as a solution.

EVs will stabilise in the future. There’s no running away from EVs because conventional fuel is not sustainable and the pollution from gasoline vehicles are toxic. Ethical issues can be addressed as the market matures.